Precision engineering

DON FOSTER is a master of precision engineering in an air-conditioned workshop.

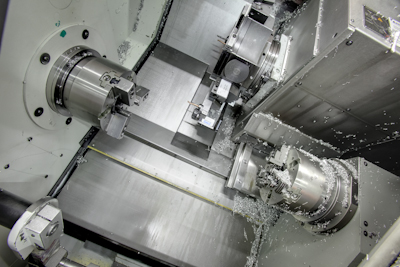

We can design, machine and assemble your metal parts and assemblies (including all steels, including 15CDV6, all alloys, aluminium, titanium ...) in our workshops. We perform all milling, turning and grinding operations by CNC 3, 4 and 5-axis machining.

The manufacturing capabilities of our machine tool offer a large reactivity and production capabilities adapted at your demands/orders.

Our workshops can support prototyping tasks or the production of small and medium runs.

We have particularly selected 15CDV6 steel to meet your motorsport and aeronautical requirements. This is the best option for solving the technical and economic problems you encounter.

Utilization and machining in annealed or treated condition present no particular difficulty. In treated condition, it is possible to perform rolling or bending operations with radii greater than 2.5 times the thickness. A specially developed heat treatment achieves excellent results from flow-turning.

Resources Prototypes - Unit Productions

HAAS 3-axis 1600x800 machining centre.

DECKEL MAHO DMC 103V 3-axis 1000x500 machining centre.

DECKEL MAHO DMU 70 EVO 5-axis 750x600 machining centre.

DECKEL MAHO DMU 50 EVO 5-axis 500x450 machining centre.

MIKRON VCE 1000 4-axis 1000x500 machining centre.

MIKRON VCE 1600 4-axis 1600x500 machining centre.

HITACHI VS60 1000x600 machining centre.

SOMAB 350 CNC lathe.

GILDEMEISTER CTX310 twin-spindle lathe.

HURON conventional milling machines.

CAZENEUVE and COCHESTER conventional lathes.

Resources Small, Medium and Large Volumes

2MITSUI SEIKI HU50 4 axis milling centres in parallel with SCHULER 20 pallets stacker

3 axis milling centre with MATSUURA FX1 in UGV divider (spindle 30000rpm)

3 MATSUURA 4axis milling centres bi-pallets

MAZAK Horizontal axis milling centre

MAZAK VTC 800 5 axis milling centre

DECKEL MAHO DMU HU 50 EVO 3 axis palletized at 4 pallets.

MORI SEIKI 5 axis two spindle turning centre (MT2000 Type)

2 INDEX ABC two spindle lathes in parallel with loading magazine of 3m

2 HARDINGE Precision lathes CHNC type.